GeeKee CeeBee

Welcome to GeeKee CeeBee's Page: House of Mechatronics Projects & Lessons.

Contact Email: Ceebee1108@gmail.com

Follow me on Youtube

__________________________________________________________________________________________________________________________________

PID DC Motor Position Control

Components List

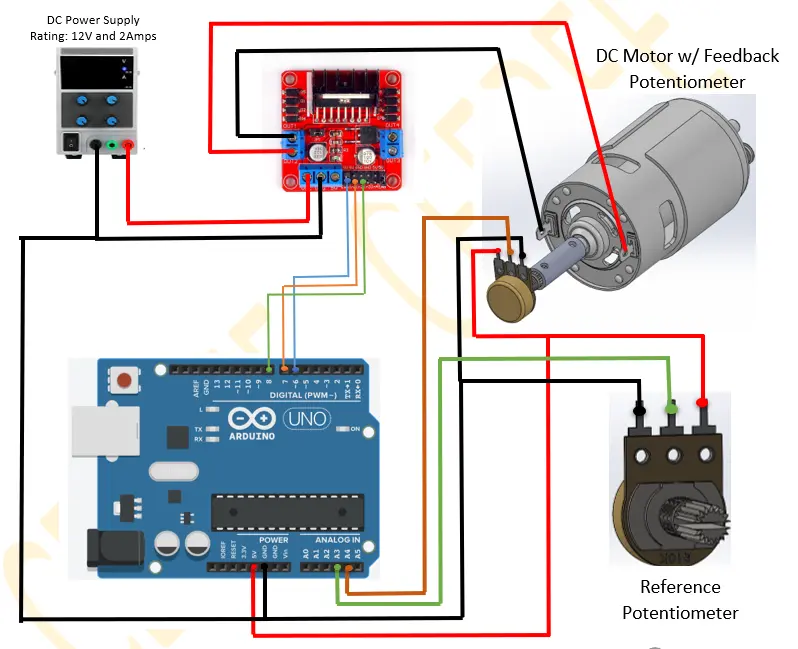

Arduino Uno (Affiliate Link)

DC Motor Double-ended Shaft (BestTong 775)

L298N Dual H-bridge Motor Driver (Affiliate Link)

2X Rotary Potentiometer (Affiliate Link)

Shaft Coupler (Custom)

DC Power Supply (6-12V)(Affiliate Link)

Jumper Wires and Breadboard (Affiliate Link)

Step-by-step video guide

Control Diagram

Wiring Diagram

__________________________________________________________________________________________________________________________________

Arduino Code

//GeeKee CeeBee

// ************ DEFINITIONS************

int potPin = A3; // Reference Potentiometer

int encoder_pot = A2; // Position Feedback sensor

int val = 0;

int encoder_val =0;

float kp = 0.2;

float ki = 0.00000 ;

float kd = 2.00;

float Theta, Theta_d;

int dt;

unsigned long t;

unsigned long t_prev = 0;

int val_prev =0;

float e, e_prev = 0, inte, inte_prev = 0;

float Vmax = 12;

float Vmin = -12;

float V = 0.1;

const byte PWMPin = 6;

const byte DirPin1 = 7;

const byte DirPin2 = 8;

//***Motor Driver Functions*****

void WriteDriverVoltage(float V, float Vmax) {

int PWMval = int(255 * abs(V) / Vmax);

if (PWMval > 255) {

PWMval = 255;

}

if (V > 0) {

digitalWrite(DirPin1, HIGH);

digitalWrite(DirPin2, LOW);

}

else if (V < 0) {

digitalWrite(DirPin1, LOW);

digitalWrite(DirPin2, HIGH);

}

else {

digitalWrite(DirPin1, LOW);

digitalWrite(DirPin2, LOW);

}

analogWrite(PWMPin, PWMval);

}

void setup() {

Serial.begin(9600);

pinMode(DirPin1, OUTPUT);

pinMode(DirPin2, OUTPUT);

}

void loop() {

val = analogRead(potPin); // Read V_out from Reference Pot

encoder_val =analogRead(encoder_pot); // Read V_out from Feedback Pot

t = millis();

dt = (t - t_prev); // Time step

Theta = val; // Theta= Actual Angular Position of the Motor

Theta_d = encoder_val; // Theta_d= Desired Angular Position of the Motor

e = Theta_d - Theta; // Error

inte = inte_prev + (dt * (e + e_prev) / 2); // Integration of Error

V = kp * e + ki * inte + (kd * (e - e_prev) / dt) ; // Controlling Function

if (V > Vmax) {

V = Vmax;

inte = inte_prev;

}

if (V < Vmin) {

V = Vmin;

inte = inte_prev;

val_prev= val;

}

WriteDriverVoltage(V, Vmax);

Serial.println(Theta_d); Serial.print(" \t");

Serial.print(Theta); Serial.print(" \t ");

t_prev = t;

inte_prev = inte;

e_prev = e;

delay(10);

}